An Astronomical Collapse: Implications of Engineering Design Decisions on the In-Service Performance of an Unprecedented Structure

This post is written by Maintainers community member Julie Mark Cohen. See her bio below.

During the Cold War by the mid-late 1950s, the U.S. military conceived the Arecibo Observatory “to aid in the research and development of ballistic missile defense systems,”[1] not originally as an observatory for radio astronomy. Specifically, the concept was driven by “a desire to better understand the composition of the ionosphere and how it might impact objects passing through, including ballistic missile reentry vehicles carrying nuclear warheads, was a key reason for its construction.” [2]

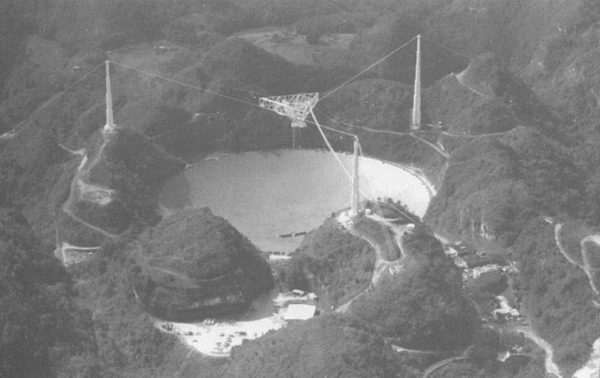

On November 6, 1959, Cornell University signed a contract with ARPA[3] to conduct studies that would lead to the development of a large-scale ionospheric radar probe that might also be used in radioastronomy and other scientific fields. Four years later, on November 1, 1963, an inauguration ceremony was held in Arecibo, Puerto Rico for the Arecibo Observatory[4] that had been constructed into a natural sink hole that accommodated the geometry of the 1000 ft (305 m) spherical reflector dish (Fig. 1 and, after 1990s modifications, Fig. 2). Fifty-seven years later, on December 1, 2020, the Arecibo observatory telescope collapsed. Steel tension cables that suspended the telescope’s 900-ton instrument platform broke[5],[6] and the platform fell 450 ft (137 m) onto the reflector dish below, rendering the observatory unrepairable.

The Arecibo Observatory was an unprecedented structure whose design required “pushing the envelope.” Given the recent collapse, this raises several questions. Did the design engineers (fail to) recognize historically-established, available, pertinent engineering knowledge for the overall structural design and for detailing of connections? How did the design engineers’ decisions impact the development of inspection and maintenance practices and repairs of this a one-of-a-kind structure? What lessons can be learned for future engineered artifacts?

To provide a fuller history of why engineered artifacts fail before planned obsolescence, we need to examine the engineering design decisions made early on, during conceptual and schematic design. In doing so, we can obtain a broader perspective on failures studies that will lead to recommendations for engineering practice to reduce the risk of future failures and their associated costs to society.

For the Arecibo Observatory, we need to turn the clock back to 1959 and briefly explore the pertinent knowledge that was available to the structural engineering designers at that time. For this article, the main source of engineering information was found in two oral histories.[7],[8] (Due to COVID-19, access to printed documentation is not available at this time.)

The following are five areas in which I found historical information that may have been overlooked by the engineering designers of the Arecibo Observatory:

Prediction of Structure Lifespan

- Were design criteria established to predict the lifespan of this structure? If yes, who set them: the military, the design engineers, or the users of the structure?

- Did the military expect this structure to last for only 10 to 15 years or until a peaceful end of the Cold War? If yes, did this short lifespan assumption influence what seems to have been lower factors of safety for the cables than would have been required for suspension bridges?

- Did the military conduct any research, such as forecasting,[9] a mathematical field that utilizes probability theory that found its early roots during World War II, to calculate the most probable lifespan based on the decisions made by the design engineers?

Environmental Loads Imposed on the Facility

- The effect of ambient temperature with respect to tension in the cables and the need to keep “fixed points” was discussed in the second oral history.

- Aeolian vibration, a high-frequency, low-amplitude motion, can occur daily in cables from non-turbulent winds below 15 mph. By the late 1950s in the electric power industry, research work was completed on “the development of rugged equipment for the field measurement of aeolian vibration” in conductors (i.e., transmission lines).[10] For the Arecibo Observatory, the oral histories indicated that experts studied aeolian vibration of the cables during design. However, Phoenix et al. (1986)[11] noted that a remedial measure was taken “in the mid 1960s [when] Stockbridge dampers were installed to minimize aeolian vibration (which had existed, though on a minor scale).”

- Hurricanes were discussed in both oral histories, noting that “the basic design parameter [was] to withstand winds of 140 mph [and] to operate within tolerance in winds up to 30 mph.” These criteria were likely based on the 1959 state of knowledge.

- Puerto Rico has been subjected to violent earthquakes, including the October 11, 1918, San Fermin earthquake. Yet, no mention was made in the oral histories of earthquake-resistant design. Since July 1959 [five months before ARPA’s awarded contract], the Structural Engineers Association of California’s Recommended Lateral Force Requirements and Commentary, “has been at the vanguard of earthquake engineering in California and around the world.”[12]

Structural Redundancy and Factors of Safety

- The Arecibo Observatory had three towers outside the reflector disk to support the platform. If one tower had failed, the entire observatory would have failed. A redundant solution might have had two side-by-side towers at each of three locations or six towers equally spaced around the perimeter of the reflector dish. The concept of redundancy dates back to the period after the first industrial revolution when it was used to improve reliability of new machines that had been exhibiting failures. More recently starting in the 1950s, engineering fields involved in defense relied upon redundancy to improve reliability of engineered artifacts.[13]

- The original four main cables each with 200 wires and the five backstay cables connected to “saddles” at each tower were designed with a factor of safety. From Phoenix et al., the original factor of safety was 2.04 for the ratio of the minimum breaking strength divided by each cable tension supporting only dead load of the equipment-loaded platform at 90° F (32.2° C). At 70° F (21.1° C) with 100 mph (161 kmh) winds, the factor of safety decreases to 1.79. When one of the cables broke on November 10, 2020, the factor of safety in each remaining cable decreased to 1.53 and 1.34, respectively. This does not take into account further reductions due to dynamic loading and the condition of the remaining three cables. A much larger factor of safety is typically used for tension-only members that tend to fail suddenly, without warning.

Galvanizing and Stress Corrosion of Exterior Wires in Cables

- During the 1930s in the U.S., laboratory studies were conducted at the National Bureau of Standards on fatigue properties of uncoated and zinc-galvanized coated steel wires of various strengths.[14] In the early-mid 1950s, papers were published in Great Britain and elsewhere on the theory of hydrogen embrittlement and stress corrosion cracking.[15] Hydrogen embrittlement can occur with presence of diffusion of hydrogen (from manufacture and/or exposure to water), a susceptible material, and high or varying stress levels.

- For the Arecibo Observatory, the wires of the cables were galvanized, but, during regular inspections, fractures were found in exterior wires of several cables at locations of particularly high tensile stresses in the exterior wires. Also, the oral histories and Phoenix et al. noted that, a remedial measure was needed to protect the backstay cables from moisture. A jacket was placed around the lower cable ends “to permit the pumping of dry air into the cable for the purpose of keeping the interior dry.”

- Phoenix et al. summarized that “ultimate wire strength is a carefully controlled variable that translates well (through mechanical analyses) to cable strength. Wire fatigue strength, on the other hand, is highly variable and sensitive to environmental and processing factors.” The uncertainty of wire fatigue strength has direct implications for the types and frequency of inspections and maintenance.

Fatigue and Fracture of Welded Hangers in Suspended Platform

- The history of fatigue and fracture of metals dates back almost 200 years.[16] All fractures occurred at geometric discontinuities, many at/near welds, rivets, or bolts. One notable failure occurred when many of the Arecibo Observatory’s structural engineering designers and other engineers and scientists were young men serving in World War II. This was the 1943 Liberty Ships’ fractures that initiated at corners of square hatch doors and, in the case of The Schenectady, was followed by a disproportionate fracture through the entire ship from deck to keel.[17]

- In the first oral history, the late Prof. William McGuire pointed out that “fatigue cracking was occurring in the [platform connection] hangers of welded design, and no obvious repair procedure would preclude re-initiation of cracking. A new design using a solid member, without welds was shown to decrease substantially the likelihood of initiation of fatigue cracking and was implemented.” The interviewer, Dr. Donald B. Campbell said, “It seemed like the single steel plates with the tapered shim seemed a lot more elegant and a simple design. I was fully surprised that hadn’t been the original design.”

The oral histories and several documents (not cited herein) included statements that the inspections such as ultrasound tests were conducted “periodically” (but without noting a schedule) to detect cracks and that maintenance was performed. That is, for the Arecibo Observatory, inspection, maintenance, and repair practices were nonstandard. Here, many of these practices were likely developed over the years in response to the failures that occurred.

As an unprecedented structure, the Arecibo Observatory was not unique regarding maintenance practices. If the continued safe performance of the structure is contingent upon inspection and maintenance, then the original design should take both into account. How do we maintain these engineered artifacts for which there are no maintenance standards? How do we prepare for in-service performance from structures that degraded due to unanticipated loads?

My conclusions are as follows:

- Engineering design practices need to ensure inspectable, maintainable engineered artifacts with reliable, predictable, long-term performance once they are placed in service.

- Undergraduate engineering education in a specific field should be broadened to include design examples from related engineering fields to provide students with what I believe are invaluable technical analogies that serve to strengthen thinking on design and detailing.

- Engineering professors should present information on historical precedent in design practice. That is, they should recount how engineering knowledge is acquired through laboratory experimental programs and tempered by failure investigations and then developed into codified documents through consensus of technical committees. From this, risks of reaching beyond what is known should also be given.

- Senior practitioners should also offer guidance to younger engineers on precedent, how design decisions are made, and how design decision relate to reliable, predictable structures, as well as profit and schedules.

- Codes for structural design are changing toward performance-based design which is supposed to lead to predictable structure performance when subjected to defined loading. However, this approach says little about identification and use of engineering knowledge or an appreciation of the consequences of unpredicted performance or unexpected loading.

- Given the above five points, a discussion is needed on what should be the source(s) for change, starting with university education.

Figure 1. Aerial view of the Arecibo Observatory showing its location in a natural sinkhole in the hills of north central Puerto Rico. <https://history.nasa.gov/SP-4218/ch4.htm>

Figure 2. More recent aerial view of the Arecibo Observatory with 1990s modifications. <https://www.darpa.mil/about-us/timeline/arecibo-observatory>

About the author:

Julie Mark Cohen, PhD, PE, SECB, is a Consulting Structural and Forensic Engineer with over 35 years of practical experience with preliminary design and peer review of structural framing of buildings and forensic investigations of failed large buildings and specialty structures. She is also an Independent Science and Technology Studies scholar. Her research starts with the creation of engineering knowledge, its carriers, conveyors, users, and post-failure feedback loops. Her interests continue with engineering design decision-making, particularly the use of extrapolation in the guise of innovation, conjectured knowledge, and implications on in-service performance of engineered artifacts. Her in-progress book is entitled Unintentional Engineering Failures by Design. Dr. Cohen can be reached at [email protected]

References

[1] Butrica, Andrew J. (1996). To See the Unseen: A History of Planetary Radar Astronomy, SP-4218, Chapter 4, “Little Science/Big Science,” NASA History Office, Washington, D.C. <https://history.nasa.gov/SP-4218/ch4.htm>

[2] Trevithick, Joseph (2020). “Collapsed Arecibo Radio Telescope was Originally Built for Ballistic Missile Defense Research,” The WarZone, Dec. 1. <https://www.thedrive.com/the-war-zone/37898/collapsed-arecibo-radio-telescope-was-first-built-for-ballistic-missile-defense-research>

[3] “Where the Future Becomes Now,” Defense Advanced Research Projects Agency, <https://www.darpa.mil/about-us/darpa-history-and-timeline> Note: The Advanced Research Projects Agency (ARPA) later became known as the Defense Advanced Research Projects Agency (DARPA).

[4] “Arecibo Observatory,” Defense Advanced Research Projects Agency (DARPA), <https://www.darpa.mil/about-us/timeline/arecibo-observatory>

[5] “Video: Footage of Collapse Arecibo Observatory,” Arecibo Observatory: Media Resources, National Science Foundation, Dec. 3, 2020. <https://www.nsf.gov/news/special_reports/arecibo/>

[6] Manley, Scott (2020). “Analyzing Video Footage of Collapse of Massive Arecibo Telescope,” YouTube, Dec. 4. <https://www.youtube.com/watch?v=59WQIRvezzI>

[7] Campbell, Donald, Interviewer and Director of the Arecibo Observatory 1981-1987, “A Conversation with Bill McGuire: A Contribution to the Oral History of the Arecibo Observatory,” eCommons, Cornell University, Video recording date not given. Issued Dec 17, 2011. <https://ecommons.cornell.edu/handle/1813/41189>

[8] “A Conversation by three Arecibo Observatory Pioneers: William F. Gordon, Dale R. Corson, and William McGuire,” eCommons, Cornell University, Video recording date not given. Issued Sept, 14, 2015. <https://ecommons.cornell.edu/handle/1813/41205>

[9] Armstrong, J. Scott (1967). Long-Range Forecasting: From Crystal Ball to Computer, John Wiley & Sons, New York, NY, 612 pp.

[10] Preformed Line Products (2013). “Aeolian Vibration Basics,” pg. 9. <http://www.preformed.com/images/pdfs/Energy/Transmission/Motion_Control/VORTX_Vibration_Damper/EN-ML-1007-4AeolianViBook.pdf>

[11] Phoenix, S. Leigh; Johnson, Herbert, H.; and McGuire, William (1986). “Condition of Steel Cable after Period of Service,” Journal of Structural Engineering, American Society of Civil Engineers, Vol. 112, No. 6, June, pp. 1263-1279.

[12] Seismology Committee (2009). “SEAOC Blue Book: Seismic Design Recommendations,” Structural Engineers Association of California, Sept. <https://www.seaoc.org/store/download.aspx?id=3DB58D21-2437-4522-B6B3-0511402E88A2>

[13] Bley, Dennis C.; Droppo, James G.; and Eremenko, Vitaly A. (2000). Risk Methodologies for Technological Legacies, Proceedings of the NATO Advanced Study Institute on Risk Assessment for the Cold War Facilities and Environmental Legacies, Bourgas, Bulgaria, 2-May 11, pg. 8. <https://web.uni-plovdiv.net/vedrin/books/Bley_et_al._Risk_Methodologies_for_Technological_Legacies.pdf>

[14] Shelton, S.M., and Swanger, W.E. (1935). “Fatigue Properties of Steel Wire,” Journal of Research of the National Bureau of Standards, Jan., pp 17-32. <https://nvlpubs.nist.gov/nistpubs/jres/14/jresv14n1p17_A1b.pdf>

[15] Petch, N.J., and Stables, P. (1952). “Delayed fracture of metals under static load. Nature, Vol. 169, pp. 842-851. Also, Petch, N.J. (1956). “Lowering of fracture stress due to surface adsorption,” The Philosophical Magazine: A Journal of Theoretical, Experimental, and Applied Physics, vol. 1, pp. 331-337.

[16] Ribeiro, Alfredo Silva; Correia, Jose A.F.O.; and De Jesus, Abilio M.P. (2011). “Evolution of Fatigue History,” Proceedings of COBEM 2011, 21st Brazilian Congress of Mechanical Engineering, Oct. 24-28, 11 pp. <

https://www.researchgate.net/publication/299397997_EVOLUTION_OF_FATIGUE_HISTORY>

[17] Zhang, Wei (2016). “Technical Problem Identification for the Failures of the Liberty Ships,” Challenges, Vol. 7, No. 20, pp. 1-8. <doi:10.3390/challe7020020>